What we do.

-

What sets us apart from most stamping facilities is our ability to design and build a die and run it in house. We have presses from 5 tons to 200 tons. This eliminates the need to outsource the tooling, resulting in a lower price per part for the customer. We also run customer owned dies for low or high volume production and do production machining of any volume, whether it is one operation or a complete part, start to finish.

-

We have seven milling machines which range in size up to our 40” x 20” vertical machining center.

-

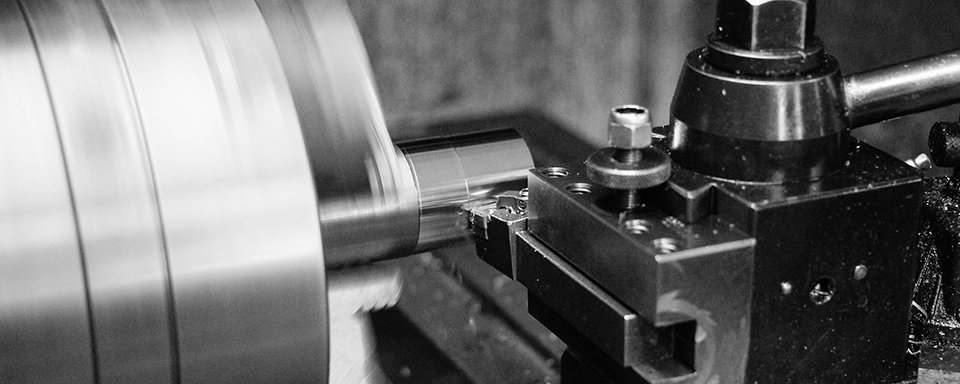

We can turn parts of all sizes at Progress Tool and Die. Our largest lathe has a 42” swing and a distance of 60” between centers.

-

We can surface grind parts of all sizes up to 24” x 48”. We also have O.D./I.D. and jig grinding capabilities.

-

With four wire EDM’s we are capable of handling short prototype runs all the way to building precision fine blank dies and everything in between.

-

With two heat treat ovens we are able to harden steel up to 10” x 15” in house which helps us to achieve the fastest lead time possible. Should the need arise to outsource, we work with several companies to ensure the best turn-around time.

-

We use AutoCAD and Keycreator to design tooling and fixturing from a customer’s print or CAD geometry. In most cases we are able to reverse engineer a sample machine part or die detail when no print is available.

-

All of our inspection equipment is calibrated to NIST and ISO 9001:2015 standards annually. This includes everything from a toolmaker’s micrometers to our CMM.

What we use to do it.

-

• 5 Vertical Milling Machines

• 1 Prototrak 3 Axis Milling Machine

• 1 Fadal 4020 Vertical Machining Center

-

• 5 Manual Lathes

• 1 Prototrak CNC Lathe

• 1 Haas ST30 CNC Lathe

-

• 4 Manual Surface Grinders

• Clausing 12×24 Hydraulic Surface Grinder

• Acer 24x48x21 Hydraulic Surface Grinder

• Moore Jig Grinder

• Grissetti O.D./I.D. Grinder

• K.O. Lee Cylindrical Grinder

-

• Sodick A530D

• Sodick A500W

-

• 2 Drill Presses

• Hercules Radial Drill Press

• 2 Electric Heat Treat Furnaces

• ELOX Sinker EDM

• Vertical and Horizontal Band Saws

• B&S Microhite DCC Coordinate Measuring Machine

-

• Dennison 5 Ton Press

• Dennison 6 Ton Press

• L&J 80 Ton Punch Press

• Federal 150 Ton Punch Press

• Clearing 200 Ton Punch Press

-

• 2 Miller Wire Welders

• Peer Resistance Welder

• Airco Heliarc Welder